APR

Activity description

APR vision is “being Customer’s choice for fluid-dynamics components in Aviation and Space”: we design, industrialize and manufacture components, leveraging our vertical-integrated structure.

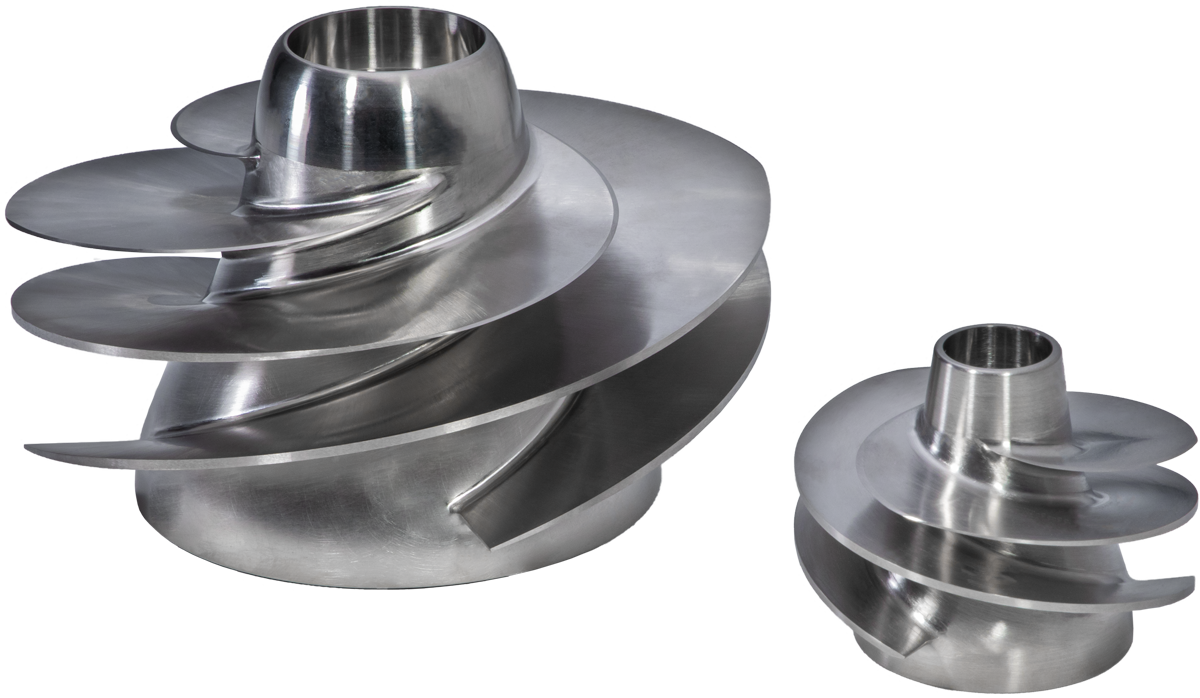

The rock-solid base is our industrial know-how: since 1998 we manufacture fluid dynamics critical parts (inducers, impellers, BLISKs/IBRs), engine components (hinges, casings) and accessories (filler caps, engine turning systems, helicopter gearbox cooling fans).

Progressively APR integrated special productions and prototyping (airfoils, full turbine demonstrators, additive-parts machining).

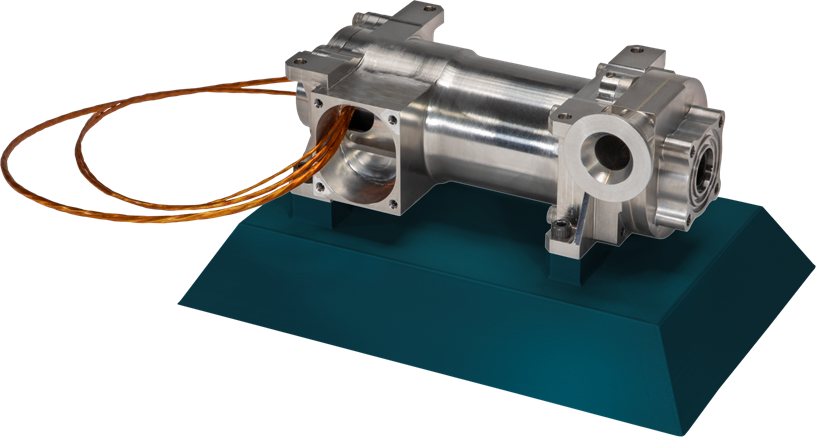

From 2019 APR developed the internal RD&E team, nowadays counting 30% of employees. We offer turn-key solutions via E2E “design-to-production” process for Valves, Pumps and Heat Exchangers, working in different contexts.

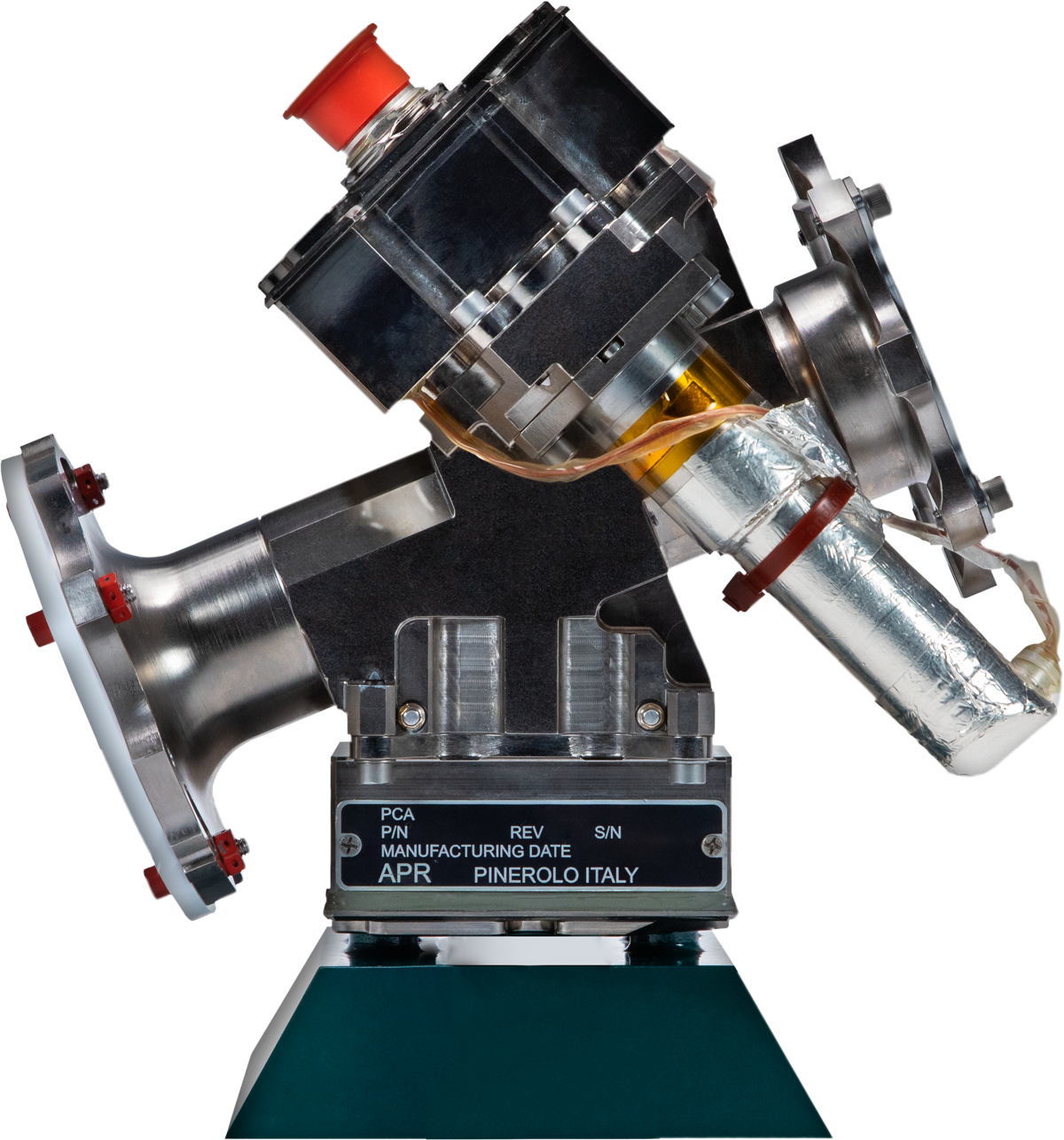

It started with Space: we proudly fly our ECLSS Valves on Cygnus and soon on HALO.

We supply Active Thermal Control System (fluidic pumps, mixing and on-off valves) to I-HAB, and Propulsion (solenoid) Valves & Pumps for ARIANE, VEGA-E and EL3 studies.

In the last year our product line expanded towards Aviation, where APR started on Fuel Pumps, low pressure Oil Valves, and more are in progress.

Products

Aircraft Systems / Structure / Metal components / Sub Assy / Propulsion Systems / Rotating Components / Stationary Components / Accessories / Sub Assy / Equipments / Hydraulic System

Space Systems / Platform / Thermal and Env. Control / Propulsion and RCS

Processes

Design / Modelling & Simulation / Drafting / SW/HW development

Manufacturing / Machining / Milling / Turning / Cutting

Miscellaneous / Assembly & Test / Operation & Logistics